Technical Solutions

Rack Tech. specializes in installing and dismantling all types of material handling systems, to guarantee you a quality and consistent crew on each job, Our Team is highly skilled supervisors, certified forklift operators and experienced labourers. We pride ourselves on working in the safest possible manner and adhere to strict OSHA safety guidelines. We provide competitive pricing with assured quality and reliability. Let us help you meet your objective with our experience that spans two decades in the industry.

PROJECT MANAGEMENT

2.We prepare necessary documentation for the implementation

3.Project initiation coordination meetings of the implementation with the customer. We coordinate and manage construction processes with other companies at the construction site.

5.The implementation team ensures take over of the construction site, as well as execution and coordination activities in the meantime and final project handover including related documentation according to the specification.

6.Handover of complete documentation: Measurement protocols, Handover protocol, Quality check report, Site diary.

WHO WE ARE

Rack Tech Middle East has been a trusted name in rack installation in G.C.C. Our company specialized in the design, Engineering & Installation of different types racking systems, but also technologically advanced racking systems of larger dimensions. We have a team of best pallet rack installers in the industry located throughout the country, so that we can offer unmatched craftsmanship on every project.

WHAT DO WE DO

20 years of Experience in warehouse solution Industry, Expertise in racking systems for the most of the big world manufacturers. Racking installation and inspection are our primary services, but we have the skills and expertise to help with refits, repairs, removals and relocations. We provide highly skilled supervisors, certified forklift operators and experienced labourers. We prepare and arrange all required documentation respecting also special or local conditions.

QUALITY

All racking installation drawings are reviewed by our project engineers to verify compliance with building codes, load applications, rack configuration drawings, and rack component manufacturer’s requirements. Quality is of paramount importance to all team members at Marshal..

SAFETY

Our employees are regularly trained in the safety of work at least once a year minimum and all people are trained & certified to work at heights. Few are certified to drive forklift trucks and use hydraulic platforms & trained in first aid on each site, these certificates are valid in all over U.A.E. Our company is insured against damages up to 3 million.

COMPREHENSIVE SERVICES

We Specialize in Quality Professional Installation and Dismantling of:

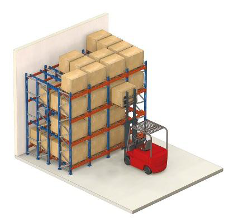

SELECTIVE RACKING SYSTEM

It provides direct access to every pallet in storage. For low turnover volume & high differentiation product lines this type of racking is a must.

DOUBLE DEEP RACKING

pallets are stored two rows deep instead of one, This increases productive use of floor space over a wide aisle system.

VERY NARROW AISLE RACKING SYSTEM (VNA)

Excellent use of space and direct access to any stored pallets. VNA Racking is the ideal choice for the optimal use of floor space and anywhere that has a narrow aisle access and high density storage needs.

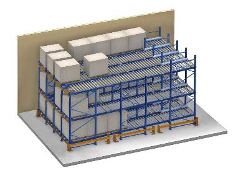

PUSH BACK PALLET RACKING

As a pallet is loaded from the front, it pushes the pallet behind it back one position. The front pallet is removed when unloading and gravity causes the next pallet to move forward automatically to the front picking position.

LIVE STORAGE PALLET RACKING

As a pallet is loaded from the front, it pushes the pallet behind it back one position. The front pallet is removed when unloading and gravity causes the next pallet to move forward automatically to the front picking position.

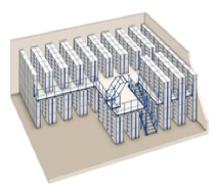

MOBILE RACKING SYSTEM

Mobile racking systems comprise pallet racking, which is mounted on mobile stands. Equipped with motors, the racking can then be moved via rail guidance so that the required racking aisle can be opened.

MODULAR MEZZANINE

Mobile racking systems comprise pallet racking, which is mounted on mobile stands. Equipped with motors, the racking can then be moved via rail guidance so that the required racking aisle can be opened.

Long Span Racking or Medium Duty Rac

Man-to-product” principle. The longspan racking is designed for warehouses where goods are deposited and removed manually from racks.

Automated Storage / Retrieval systems (AS/RS)

AS/RS are a combination of cranes, storage equipment and conveyors that are controlled by software to automatically receive orders, retrieve the SKUs for the orders from their storage locations and drop them off at a designated area.

This is a high-density pallet storage system making it easier to load and unload goods thanks to an electric carriage called a Radio-Shuttle, shuttles to move independently within the rack itself.

Set of elements designed for transporting, accumulating and/or distributing goods to specific positions required by the logistics operations.

Clad Rack Warehouses

The racking itself forms part of the construction of the building together with side and roof cladding. The ranking structure supports not only the actual goods and the different building elements but also the thrust of the handling devices and external elements: winds, heavy snowfalls, seismic movements, etc.